Company Group ABZ-1

Company group "ABZ-1" performs the full range of works related to road construction

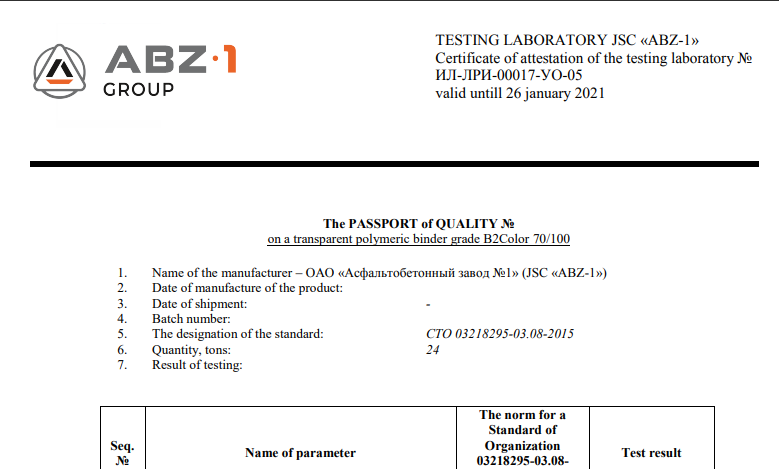

Presentation: About UsTransparent (clear) binder B2color

Colorless (clear or transparent) polymeric binder for colored asphalts.

Presentation: Colored asphalt Presentation: B2colorB2color is created in several versions, such as B2color 50/70, B2color 70/100, and B2color 100/130 —based on different weather requirements.

Product Description

is a clear, transparent polymeric substance made out of synthetic oils, resins, polymers, and other additives;

does not contain epoxy resins;

is designed to produce colored asphalt mixes;

is used in asphalt mixes in combination with the client’s preferred color or hue; for more intense colors a stone-based material of the same hue is recommended.

The typical features for the B2color 50/70 brand appear in the table below

| N | Name of the indicator | B2color 50/70 test results |

|---|---|---|

| 1 | Penetration, 0.1 mm at 25 °С | 64 |

| 2 | The softening point °C | 59 |

| 3 | Ductility, cm, at 25 °C | 90 |

| 4 | Elasticity,% at 25 °С | 96 |

| 5 | Fraаs temperature °С | -17 |

| 6 | Flash point, °C | 290 |

| 7 | Dynamic viscosity at 135 °C, Pa * s | 0.56 |

| Resistance to aging at a temperature of 163 ° ( after RTFOT) | ||

| 8 | The change in softening temperature, °C | 3 |

B2color is manufactured, stored, and delivered according to the ISO 9001 requirements.

Colored asphalt mixes made with the use of B2color can be manufactured by a variety of standard equipment.

Polymer modified bitumen

Modified bitumen is bitumen with additives from special polymers. It has found its application mainly in road surfaces.

Modified bitumen is bitumen with additives from special polymers. It has found its application mainly in road surfaces. Its appearance was due to purely technical reasons. The increase in vehicle traffic increased the load on the road surface, and conventional bitumen, which has a lower performance, often did not withstand these loads. Thus, a more advanced material was required, with better indicators of strength in relation to the road surface and more convenient in storage, use, etc. The addition of polymers to bitumen solved this problem. Modified bitumen has increased elasticity, which makes it more resistant to deformation. The temperature difference for modified bitumen ranges from one hundred degrees, while for ordinary bitumen there is only sixty degrees between brittleness and softening. In addition, practice has shown that even after ten years of use as an asphalt concrete pavement, modified bitumen does not lose its viscosity.

A number of polymers for various purposes are used to modify bitumen. They can be conditionally divided into several groups. Thermoplastics soften when heated and harden when cooled. At normal temperatures, modified thermoplastic bitumen increases its viscosity and hardness, while maintaining elasticity at the same level.

Elastomers, in accordance with the name, increase the elasticity of bitumen at normal temperatures, and with large temperature fluctuations, they can keep it at a high level. Bitumen with elastomers retains its properties in frost and temperatures up to two hundred degrees Celsius. However, the storage of this type of bitumen is associated with a number of features. So, it must be constantly mixed, since elastic polymers constantly tend to separate from the bitumen base.

The third type of modified bitumen is a combination of the first two. Thermoelastics are deformed and softened only at very high temperatures. Also, to modify bitumen, natural and synthetic resin, asphalts, and some inorganic salts are often added to it.

A great influence on the characteristics of modified bitumen is exerted not only by the composition of the polymers introduced into it, but also by the method of introduction itself. That is why bitumen modification is carried out only in refineries or in special installations where this process is strictly controlled.

Bitumen-latex emulsion

Bituminous-latex emulsion has proven to be excellent binders for asphalt mixtures during repair work.

Bituminous-latex emulsion has proven to be excellent binders for asphalt mixtures during repair work. However, today there are no universal compositions of bitumen emulsions that would best suit the conditions of work. Therefore, in practice, they resort to changing their characteristics by introducing various polymers. This process in the technical literature is called modification, i.e. by combining bitumen emulsion with synthetic polymer additives.

Latex itself is a natural or synthetic dispersion of rubber particles in water. As part of a water-bitumen emulsion, latex increases the strength and elastic properties of the material. As a rule, latex polymers are combined with the aqueous phase and emulsified with bitumen directly during the preparation of the bitumen-latex emulsion. But also the bitumen itself can be modified with latex, or latex polymers prepared in the form of an independent emulsion can be introduced into the finished bitumen emulsion.

Latex polymers can be of cationic, anionic and nonionic types, depending on the charge of its particles. It is imperative to take into account the compatibility of the latex and the emulsion, since the aqueous polymer dispersion must correspond to the characteristics of the emulsifier.

One of the most well-known is a latex additive, which makes it possible to obtain a product such as a bitumen-latex emulsion at the output. The addition of latex makes it possible to increase the strength and mechanical properties of the emulsion. In structure, it is a natural or synthetic dispersion of rubber in water.

When preparing emulsions, it is imperative to take into account the type of latex polymer, which is determined by the charge of its particles. After all, not every latex (cationic, anionic and nonionic) can be compatible with a particular type of emulsion.

In addition to road construction, bitumen-latex emulsions are successfully used as waterproofing materials for building structures, protecting them from water penetration and its subsequent destructive effect.

The advantage of using bitumen-latex emulsions is noted by a number of qualitative indicators: the period of operation of roads increases, the temperature range of operability expands, the time of layer formation is reduced, high elasticity and resistance to deformations are provided. To improve the adhesion of layers, experts recommend adding special adhesive additives to latex-bitumen emulsions.

History

-

Company group "ABZ-1" with a total turnover of about 7 billion rubles a year and a staff of over 1000 people occupies a stable position in the field of road construction and the production of road-building materials, conducts successful research and development work.

-

The ABZ-1 group of companies continues to increase its presence in the regions. In 2009 the specialists of ABZ-1 Group of Companies perform as consultants in the construction of a pavement made of cast asphalt concrete on one of the largest bridges in Russia across the Volga river in the city of Ulyanovsk. On July 30, 2014, Asphalt Concrete Plant No. 1 solemnly opened in Pushkin (near of St. Petersburg) a new, at that time the most modern in Russia production complex of two Benninghoven CONCEPT TBA -4000 plants with a capacity of 640 tons of products per hour. In 2015, ABZ-Dorstroy will start implementing large infrastructure projects for the 2018 FIFA World Cup in St. Petersburg and Kaliningrad. In 2017, the Group of Companies celebrated its 85th anniversary!

-

In 1994, open joint-stock company "Asphalt concrete plant No. 1" for the first time in the North-West region of Russia uses gabbro crushed stone and improved road bitumen for production of asphalt concrete mixtures. From 1994 to 2004, Asphalt Concrete Plant No. 1 produced over 4 million tons of asphalt (including about 2.5 million tons of high-quality asphalt intended for the upper layers of road surfaces). In 1999, the company's development strategy places particular emphasis on expanding contracting activities and integrating divisions. In 2004, ABZ-1 initiated experiments in the production and laying of colored asphalt concrete mixtures. In May 2005, ABZ-1 put into operation a modular asphalt concrete plant Amomatic (manufactured by Amomatic OY, Finland) with a capacity of 240 tons per hour. In the same year, the enterprise started the industrial production of mineral powder activated by waste from the pulp and paper industry and bitumen.

-

In 1979, a second asphalt concrete production plant was organized in the North Western part of the city. In 1993 the plant becomes a joint stock company, and its development strategy approves the production of only high quality products based on the introduction of advanced technologies. In total, from 1932 to 1993, the enterprise produced over 15 million tons of asphalt.

-

The plant comes into operation after total reconstruction and starts to produce asphalt concrete mixture.

-

With the start of the construction season in 1947, Asphalt Concrete Plant No. 1 starts producing asphalt concrete mix. Due to this the increase by 2,5 times of the area of new asphalt concrete pavements on the city streets was achieved. The design and the construction of a new asphalt concrete plant is underway. In terms of the equipment of the main building, the plant has no analogues: in one building there are mixing, drying-grinding and stone crushing units, railway tracks and a warehouse of inert materials. For the first time, the supply of inert materials to the receiving bins began to be carried out by grab bridge cranes. A closed-type bitumen storage facility with steam heating and access railway lines, bitumen-melting units and a boiler house are located in separate buildings located at a considerable distance from the main building.

-

During the WWII the main task of the factory was to perform all work related to the elimination of the damage after the raids of fascist aircrafts bombing and shelling. Within two years from 1941 to 1943, over 40 thousand m2 out 46 thousand m2 of damaged road surfaces in Leningrad were restored.

-

The future Asphalt Concrete Plant No. 1 was founded in 1932 and later became the first specialized enterprise in St. Petersburg for the production of asphalt concrete mixtures for construction, roadway repair and landscaping. The most important event of 1938-1940 in the construction of road surfaces is almost complete replacement of St.-Petersburg pavements from wooden to concrete ones

thumb.png)